The Future of HVAC Filtration: Trends Shaping 2025

In 2025, HVAC filtration is being reshaped by rising indoor air quality demands, stricter regulations, and smart building technology. Emerging solutions like nanofiber media, antimicrobial coatings, and IoT-enabled monitoring are delivering cleaner air, better energy efficiency, and longer service life—especially in sectors like healthcare, data centers, and modern office buildings.

The Future of HVAC Filtration: Trends Shaping 2025

Introduction

The HVAC filtration industry is undergoing unprecedented growth and transformation in 2025. With heightened awareness of indoor air quality (IAQ) and stricter health regulations post-pandemic, demand for advanced air filters has surged globally. Market analysts project the global HVAC air filters market to reach $14.08 billion by 2035, growing at about 5% annually1. This boom is driven by factors like rising health consciousness, new building codes, energy efficiency goals, and smart building innovations. In short, HVAC filtration has moved from a building afterthought to a forefront concern for public health, sustainability, and business continuity.

Building owners and facility managers worldwide are investing in better filtration systems to provide healthier indoor environments. From hospitals upgrading to surgical-grade HEPA filters, to office towers installing smarter, sensor-enabled filter racks, the focus on clean indoor air has never been greater. As we look at the trends shaping HVAC filtration in 2025, it’s clear that emerging technologies and evolving market dynamics are driving a new era of innovation in commercial HVAC filtration systems.

Key Drivers of Innovation in HVAC Filtration

Several key market drivers are propelling innovation in HVAC filtration. Industry experts point to a convergence of post-pandemic health priorities, environmental regulations, and technological advancements as catalysts for change. The main forces include:

- Post-Pandemic Indoor Air Quality Focus: COVID-19 put a spotlight on IAQ, leading businesses to upgrade ventilation and filtration to reduce airborne viruses. Many buildings have added enhanced HVAC filters and even UV disinfection to continuously purify the air and make indoor spaces safer. High-efficiency filters (MERV 13 and above) are increasingly standard in offices, schools, and public venues as a first line of defense against aerosols and pollutants.

- Stricter Regulations and Standards: Governments and professional bodies have responded with tougher air quality and filtration standards. For example, California’s building code now mandates MERV 13 or higher filters in all mechanically ventilated buildings4. ASHRAE’s latest guidelines and the new ASHRAE Standard 241 (2023) for infectious aerosol control push facilities toward higher filtration efficiency and ventilation rates5. These regulations ensure cleaner recirculated air and drive adoption of advanced filter products.

- Energy Efficiency Requirements: Facility managers are under pressure to cut energy usage, and HVAC fans can consume significant power pushing air through filters. Traditional high-MERV filters can restrict airflow and raise energy costs, so the demand is rising for filters that maintain high efficiency with low pressure drop. This need fuels research into new media (like nanofibers) that capture more while letting air flow freely. Efficient filters keep coils and ducts cleaner, which in turn allows HVAC systems to run with less strain and lower energy consumption. In data centers, for instance, using high-efficiency filters reduces dust on cooling coils, improving airflow and cutting energy use.

- Smart Building Integration (IoT): The rise of IoT and building automation is reaching HVAC filtration. Operators now integrate sensor-equipped filters and air quality monitors into building management systems for real-time oversight. These smart systems can track pressure drop and particle counts, sending alerts when a filter is loaded or IAQ declines. Predictive maintenance driven by IoT slashes unplanned HVAC downtime and maintenance costs by up to 40% through timely filter replacements8. Smart filters also enable on-demand ventilation adjustments – for example, ramping up air exchange when occupancy or pollutant levels spike. This level of control not only optimizes air quality but also avoids energy waste by adjusting HVAC operation based on actual needs.

- Global Urbanization and Pollution Concerns: Rapid urban growth, especially in Asia-Pacific, means more HVAC systems are being installed in new buildings. In dense cities with pollution or wildfire smoke events, stakeholders are demanding better filtration to protect occupants from PM2.5, smog, and other contaminants. Green building certifications like LEED now require at least MERV 13 filters in commercial buildings12, tying air quality to sustainability and tenant well-being. Likewise, rising outdoor air pollution and recurring wildfire smoke in regions across the globe have made high-performance filters and air cleaners an essential investment for many businesses and schools.

In combination, these drivers have created a fertile environment for HVAC filtration innovation. 2025 is seeing record R&D spending by filter manufacturers and new collaborations between tech firms and HVAC companies to meet the market’s evolving demands.

Emerging Technologies and Innovations in Filtration

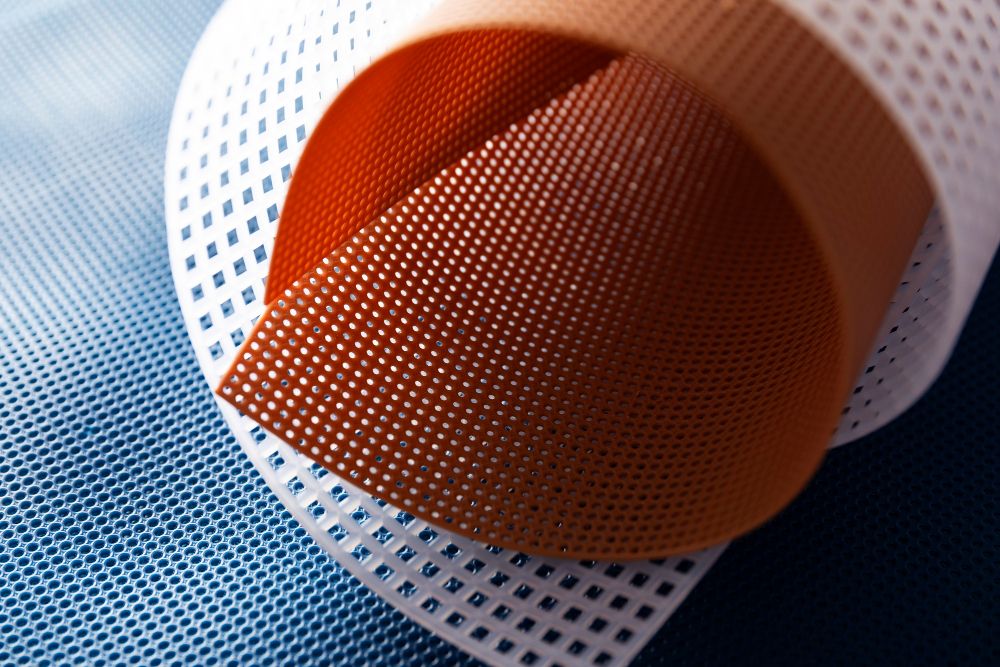

Smart filtration technology integrates advanced materials and IoT sensors to enhance HVAC performance.

Cutting-edge technologies are transforming how commercial HVAC filters perform and how they are managed. Manufacturers are introducing innovations that promise better filtration efficiency, longer service life, and real-time performance monitoring. Below we explore some of the most impactful emerging filtration technologies:

Advanced Filter Media (Nanofibers & More)

One of the most significant advances is in filter media materials. Traditional HVAC filters use fiberglass or polymer fiber mats, but newer nanofiber media and composite materials are raising the bar. Nanofiber filters are made with extremely fine fibers (hundreds of times thinner than a human hair) that present a huge surface area to capture particles. This design can trap ultrafine pollutants with high efficiency while keeping airflow resistance low. In fact, HEPA filters made with expanded PTFE nanofibers achieve the same 99.97% efficiency as conventional microfiber HEPA media at a lower pressure drop6. This means facilities can upgrade to finer filtration without paying an energy penalty in fan power. According to the National Air Filtration Association, nanofiber-integrated filter bags have been developed that exceed the dust-holding capacity of traditional filters while showing lower initial resistance at the same efficiency14. Such media maintain performance longer and reduce how often filters need changing.

Beyond nanofibers, other novel materials are emerging. Some filters now incorporate graphene coatings or fibers, leveraging graphene’s strength and thinness to trap pollutants (and even kill bacteria) with minimal airflow impact. Activated carbon and alumina coatings are being added to filter media to adsorb odors, VOCs, and toxic gases – a response to concerns like wildfire smoke and urban pollution. Multi-layer composite filters combine these approaches, for example a base layer of coarse filter for larger dust, a nanofiber layer for fine particles, and a carbon-infused layer for gases. The result is a single filter that can tackle particles and gaseous pollutants in one system, which is increasingly attractive for buildings facing diverse air quality challenges. Importantly, many of these advanced filters manage to extend service life and reduce waste, since their superior capacity means fewer change-outs. Longer-lasting filters not only cut maintenance costs but also align with sustainability goals by reducing discarded filter media.

Antimicrobial and Health-Focused Features

In the wake of the pandemic, there is huge interest in filters that not only capture pathogens but also neutralize them. Antimicrobial-coated HVAC filters are one such innovation gaining traction. These filters are treated with safe antimicrobial agents (like silver ion or specialized polymers) that inhibit the growth of bacteria, mold, and even viruses on the filter surface. This prevents the filter from becoming a breeding ground for microbes in damp conditions. For example, new mold-inhibiting filters for commercial purifiers use antimicrobial media so that captured mold spores can’t colonize the filter itself. The microbial coating gives building operators peace of mind that the filter won’t harbor or re-release biological contaminants.

Healthcare settings are especially adopting antimicrobial and even virus-inactivating filter technologies. High-end hospital HVAC filters may include a germicidal layer or UV light modules to kill pathogens on contact, adding an extra layer of protection beyond just particle capture. While true HEPA filters remain the gold standard for removing airborne microorganisms (they capture 99.97% of particles ~0.3µm including bacteria and viruses), the trend is to supplement mechanical filtration with active germicidal measures22. Studies have shown HEPA filtration greatly reduces viral bioaerosols in hospital environments, and now manufacturers are marketing “HEPA-plus” filters with embedded copper or chemical coatings that claim to eradicate trapped pathogens (for instance, the NanoFense© coating advertised to kill viruses on filter fibers24). While such claims must be vetted, the push for health-focused HVAC solutions is clear.

The pandemic also accelerated portable filtration units in commercial spaces (like HEPA air cleaners in offices or classrooms), but in 2025 we see those stopgap measures evolving into permanent HVAC upgrades. Employers and building owners are keen to provide cleaner air to boost employee wellness and productivity. This means more MERV 14+ filters in office HVAC systems (up from the pre-2020 norm of MERV 8), often accompanied by air quality monitoring to reassure occupants. Overall, whether through antimicrobial coatings, higher MERV/HEPA filters, or added UV disinfection, filtration technology is becoming ever more health-centric – aiming not just to remove dust, but also to neutralize infectious agents and allergens for safer indoor environments.

IoT-Enabled Smart Filtration Systems

HVAC filtration is also getting “smart” in 2025. IoT-enabled filters and air quality systems allow continuous monitoring and automated control of air cleanliness. These innovations address a key pain point in commercial buildings: knowing when filters are dirty or when air quality is dropping, before it becomes a problem. New sensing technologies now embed small pressure sensors and particle counters in or near filter housings. They feed data to the building’s management dashboard or even to cloud platforms. The payoff is proactive maintenance – facility managers get alerts when a filter is approaching its load capacity or if a sudden pollution event (say smoke or dust influx) occurs. This prevents the common issue of filters being left in too long (becoming ineffective) or changed too early (wasting useful life).

Smart filters tied into building automation systems (BAS) can do more than alert; they can take action. For example, if sensors detect high particle levels, an AI-driven system might temporarily boost the airflow or recirculation rate to clean the air faster, then revert to normal once IAQ stabilizes27, 28. Conversely, when occupancy is low, the system might dial back ventilation to save energy, confident that it can ramp up when sensors note people (and CO₂ levels) rising. Some commercial HVAC setups now feature adaptive filtration, where AI algorithms adjust fan speeds or damper positions based on real-time IAQ data to maintain targets with optimum efficiency. The result is cleaner air on demand without manual intervention.

The predictive maintenance aspect of IoT is a game-changer for large facilities. Rather than fixed schedules, filter replacements are done when needed, preventing both the risk of clogged filters and unnecessary swaps. Reports indicate IoT-based HVAC maintenance can cut surprise breakdowns and maintenance costs significantly – by as much as 30–40% according to field data8. Moreover, energy savings of up to 15–20% are achievable by optimizing HVAC operation with sensor feedback9. In an era of tight margins and sustainability mandates, those savings are huge. Even occupant-facing benefits are emerging: building tenants can be given dashboards or displays showing current air quality (similar to how smart thermostats show temperature). This transparency reassures occupants and demonstrates the value of the building’s filtration investments.

Several companies are now offering smart filter subscription services where the filter unit notifies the supplier when it’s time for a replacement, automatically shipping a new filter. Integration with smart home and office platforms is also growing – for instance, Matter-compatible air quality devices can seamlessly join a building’s IoT ecosystem. We are essentially seeing the HVAC filter become a connected device, part of the Internet of Things, contributing to the larger smart building narrative. Going forward, expect nearly all commercial filtration systems to include some level of sensor intelligence, given the clear benefits in uptime, efficiency, and IAQ assurance.

Sustainable & High-Performance Designs

Sustainability is another key theme in filtration innovation. Traditional HVAC filters, especially high-grade ones, often use materials that aren’t easily recyclable and end up as landfill waste. In response, manufacturers are developing eco-friendly filter designs that reduce environmental impact without sacrificing performance. One approach is reusable filters – filters made with durable frames and media that can be washed or vacuumed and re-used multiple times. Modern washable filters (some with nanofiber or electrostatic media) can maintain high MERV ratings while lasting years, drastically cutting waste and life-cycle cost33. For example, new industrial reusable filters can be hosed down and reinstalled, eliminating hundreds of disposable filters over their lifetime.

When disposable elements are necessary, companies are switching to biodegradable or recycled materials. Filter frames made of recyclable plastic or cardboard are now common, and research is exploring biodegradable filter media that break down naturally after use. The push for greener materials aligns with corporate ESG goals and green building standards. In addition, high-performance filters are being designed to have lower airflow resistance, as noted earlier, which not only saves energy but also often allows downsizing of HVAC equipment (smaller fans or motors) – indirectly reducing the carbon footprint of the building’s infrastructure.

Energy efficiency itself is a sustainability metric. The most advanced HVAC filters are now tested and rated not just on MERV or particle capture, but also on an Energy Cost Index (ECI) or similar measures of how much energy they consume over time. Products like Camfil’s “5-Star” filters are marketed for having optimized media pleat designs that can cut HVAC energy use by up to 40% while maintaining high filtration36. Such filters often carry labels from programs that certify low pressure-drop and long life. Selecting these can even contribute to LEED points or other building certification credits for optimizing energy performance and IAQ.

Overall, the future of HVAC filtration is clearly leaning toward sustainable, high-efficiency solutions. The industry is aligning health protection with environmental responsibility – a dual mandate of the 2020s. By investing in these smarter and greener filters, building operators not only protect occupants and equipment but also reduce waste and energy, creating a virtuous cycle of economic and environmental benefits.

Sector Spotlights: Filtration in Key Industries

Innovations in HVAC filtration are being adopted across all industries, but three sectors stand out as leaders in 2025: healthcare, data centers, and commercial office buildings. These environments have some of the most stringent requirements and compelling use-cases for advanced filtration. Below we examine how each of these sectors is driving and benefiting from the latest HVAC filtration trends.

Healthcare & Hospitals

In healthcare facilities, air filtration is a critical component of infection control and patient safety. Hospitals were among the first to upgrade HVAC systems in response to COVID-19, and that push continues strong through 2025. Many hospitals have moved to higher MERV filters or HEPA filtration in their HVAC systems wherever feasible, in order to capture viral aerosols and bacteria that could otherwise spread between rooms. In the early pandemic, some retrofitted portable HEPA units and negative pressure machines; now, more permanent HVAC upgrades are being implemented. It’s common to see MERV 14 or 15 filters (or better) in general hospital air handlers, whereas pre-2020 they might have used MERV 8–11 in non-critical areas. The result is significantly cleaner air throughout the facility – an important factor given that HEPA filters can remove allergens, bacteria, and viruses with 99.97% efficiency when properly applied22.

Hospitals are also investing in multi-layer filtration systems and UVGI (ultraviolet germicidal irradiation) to neutralize pathogens. For example, an office of a major hospital chain reported installing UV-C lights in ductwork alongside new final filters to continuously sterilize any microbes caught on the filters. Such dual-pronged approaches greatly reduce the risk of HVAC systems recirculating infectious particles. The ASHRAE 170 standard already mandates specific filter levels for different hospital areas (like MERV 14 for operating room supply air, and HEPA for isolation room exhaust), and compliance is taken very seriously. On top of that, the recent ASHRAE 241 infectious aerosol standard is influencing hospital designers to ensure even better air cleaning during outbreaks5.

Another innovation resonating in healthcare is the use of antimicrobial-coated filters. Given the high humidity and microbial load in certain hospital areas (e.g. damp return-air plenums, or where mold is a concern), filters with antimicrobial media prevent mold and bacteria growth on the filter itself. This is crucial because a filter that becomes colonized with bacteria or fungi could potentially release spores or odors. By inhibiting growth, these filters help maintain sanitary conditions between filter change-outs. Hospital maintenance staff also appreciate features like extended dust-holding capacity (to reduce change frequency) and improved fire resistance in filters (many modern hospital-grade filters are flame retardant for safety).

Case studies have shown the benefits of these upgrades. Facilities that improved filtration and ventilation have documented reductions in infection rates and absenteeism. The changes aren’t just for pandemic preparedness – they also help cut hospital-acquired infections from other airborne diseases like tuberculosis or fungal spores. All told, healthcare organizations view high-performance HVAC filtration as essential infrastructure for patient care. This sector will continue to be a hotbed of filtration innovation, from experimentation with in-duct air purifiers to integration of real-time IAQ monitoring in critical rooms (ensuring pressure differentials and filter performance are always in spec). When it comes to clean air, hospitals in 2025 are uncompromising, leveraging every technology available to protect patients, staff, and visitors.

Data Centers & Mission-Critical IT Facilities

Data centers might not have human occupants to protect, but air filtration is mission-critical for protecting sensitive IT equipment. These facilities house racks of servers and electronics that must be kept cool and contaminant-free to prevent failures. The year 2025 finds data center operators grappling with two challenges: explosive growth in computing demand (especially with cloud and AI workloads) and the need to manage the corresponding surge in energy consumption. High-efficiency HVAC filtration plays a key role in both protecting equipment and optimizing energy usage in these environments.

One major concern is particulate pollution – tiny dust particles can settle on circuit boards, clog server fans, and cause overheating or short-circuits. In some regions, outdoor air used for “free cooling” contains high levels of dust or industrial pollutants that must be filtered out. Modern data centers therefore use multi-stage air filtration: typically a pre-filter (MERV 8 or 11) to catch large dust, followed by a fine filter rated MERV 13 to 16 (or ePM1 60-90% in ISO terms) to remove very fine particles39. Importantly, filter makers have developed products specifically for data centers that deliver high filtration efficiency without high resistance, so cooling airflow to servers isn’t compromised. Camfil, for instance, offers filters in the MERV 15/16 range that are labeled “A” for high airflow (MERV 13A–16A) meaning they maintain efficiency even under real-life air velocities40. Using these, data centers can achieve excellent air quality without increasing energy usage for fans.

Effective filtration in data centers also yields energy and maintenance savings. By capturing more dust before it reaches cooling coils and hardware, filters keep the HVAC system internals much cleaner. This prevents the thermal transfer loss that happens when coils are blanketed in dust. One industry publication notes that as high-efficiency filters trap more particles, they reduce dust buildup on HVAC components, allowing the system to run more efficiently and potentially lowering energy consumption. Over time, this can make a significant dent in the enormous power draw of data center cooling (cooling can account for 30% or more of a data center’s electricity use). Additionally, cleaner systems mean less frequent coil cleaning and less wear and tear on fan motors – extending equipment life and uptime.

Another aspect is molecular contamination control. Data centers are increasingly worried about corrosive gases (like sulfur compounds from pollution or outgassing of materials) that can corrode circuit boards and connectors. To tackle this, some facilities install gas-phase filters (activated carbon or chemisorbent media) in the air handling units. These remove corrosive gases and protect against one of the silent killers of electronics: corrosion-induced failures. Camfil’s data center filtration guide highlights risks like sulfur-bearing gases causing corrosion, and offers specialized carbon filters to address them. In 2025, big operators running mission-critical sites (financial data centers, semiconductor fab cleanrooms for servers, etc.) often deploy real-time IAQ sensors for corrosive contaminants (for example, monitoring corrosion classification per ISA standards). When pollutant levels rise, these systems can alert staff or kick on extra filtration modules.

In summary, data centers exemplify filtration’s dual benefits: protecting equipment reliability and improving energy efficiency. As this sector grows (with edge data centers popping up in many cities and hyperscale centers expanding), the filtration market is creating tailored solutions – from high-capacity filters that last longer in dusty environments, to compact filters for edge sites, to smart sensors that integrate with facility management to ensure air quality compliance. Given the cost of downtime in data operations, the ROI on superior filtration is a no-brainer. We will see continued innovation here, such as filters that combine particle and molecular removal in one, or filters with embedded electronics that signal their status to a central control. The goal is to keep the digital world’s engine (our data centers) running smoothly on clean, cool air 24/7.

Commercial Offices & Buildings

Commercial office buildings have become a focal point for HVAC filtration upgrades, especially as companies navigate a post-pandemic return-to-work. In 2025, building owners and corporate facility managers are using air quality improvements as a selling point to lure employees back and to satisfy higher expectations for wellness in the workplace. This sector may not have the absolute critical requirements of healthcare, but it has volume: millions of square feet of office space are being refitted or newly built with state-of-the-art filtration and monitoring as part of healthy building initiatives.

A notable trend is that many offices are now upgrading from standard low-grade filters to MERV 13 or higher in their HVAC systems. ASHRAE and the U.S. EPA both recommend MERV 13 as a minimum for meaningful removal of airborne viruses and fine particles, and indeed LEED green building certification requires MERV 13 filtration throughout the building12. Pre-2020, a typical office HVAC might have used MERV 8 filters (which only trap ~20% of sub-micron particles); now, building codes in some jurisdictions mandate MERV 13 and many landlords voluntarily choose it to align with best practices. This significantly improves indoor air by capturing pollen, mold spores, and a large fraction of airborne viral particles. According to one NAIOP report, many office buildings increased ventilation rates and installed better filters and even UV lamps during the pandemic to purify air continuously, similar to the strategies used in aviation and healthcare. Those enhancements are being made permanent, not just as emergency measures.

Another driver in offices is the corporate focus on employee health and productivity. Research from Harvard and others showed that cleaner indoor air (lower CO₂ and pollutants) correlates with improved cognitive function and productivity for workers46, [47. Businesses are taking note. It’s not just about preventing disease; it’s also about everyday benefits like fewer allergy symptoms, less fatigue, and higher overall comfort. As a result, many companies are pursuing healthy building certifications such as WELL and Fitwel. These programs require ongoing IAQ monitoring and high filtration standards. The International WELL Building Institute saw a surge in registrations for healthy building certification post-pandemic, indicating how office owners are investing in air quality as part of ESG and wellness commitments. Features might include lobby displays showing air quality indices, use of air cleaning plants or botanical walls in tandem with HVAC upgrades, and regular air quality audits to ensure the building meets targets for particulate count and VOC levels.

In practice, what does a 2025 high-end office HVAC system look like? Many have two stages of filtration (a pre-filter plus a secondary filter of MERV 13-15, or even HEPA in some cases like high-traffic lobbies or high-end workplaces). They often integrate air quality sensors in return ducts and key office areas – measuring PM2.5, CO₂, humidity, etc. – feeding into the building’s automation system. Facility managers can track these metrics via dashboard and fine-tune the ventilation or identify issues (e.g., a dirty filter or a source of pollutants indoors). Some innovative offices pair filtration with IoT occupancy sensors to adjust airflow per room usage, maintaining air freshness while saving energy when rooms are empty.

We’re also seeing offices address odors and gaseous pollutants more than before. For instance, buildings in wildfire-prone regions or urban centers might add carbon filter panels to air handlers to remove smoke odors or exhaust fumes that regular particle filters can’t catch. Employee feedback has shown that odor-free, truly “fresh” indoor air improves satisfaction. All these efforts contribute to making indoor spaces not only safer in terms of infection risk but more pleasant and energizing places to work. As a side benefit, these upgrades can help a building stand out in a competitive real estate market – “clean air” has become a selling feature akin to natural light or ergonomic design.

To summarize, commercial offices are embracing a new baseline of air filtration quality. The sector’s main three priorities are health (removing contaminants that affect wellness), compliance (meeting new standards and certifications), and transparency (measuring and communicating IAQ to occupants). With advanced HVAC filtration, office buildings are turning into active promoters of occupant health rather than passive boxes. This trend is likely to continue, supported by ongoing research and perhaps future government incentives for IAQ improvements in workplaces.

Conclusion

By 2025, HVAC filtration has evolved from a mundane facility concern into a dynamic field of innovation central to healthy, energy-efficient, and smart buildings. Globally, we see accelerated adoption of high-efficiency filters, from HEPA units in hospitals to smart MERV 13+ filters in office towers, driven by post-pandemic awareness and stricter environmental regulations2, 4. Emerging technologies – nanofiber media, IoT sensor integration, antimicrobial coatings, and sustainable materials – are enabling filters to perform better and last longer while reducing operational costs. These innovations are shaping a future where indoor environments can be cleaner, safer, and more closely controlled than ever before.

Market dynamics also indicate this transformation is here to stay. With the HVAC filter market expanding steadily and new players investing in R&D, building owners have a wider array of solutions to choose from (including sector-specific products for healthcare, data centers, etc.). The convergence of IAQ priorities with energy and sustainability goals means that next-gen filters must check all the boxes – protecting people’s health, guarding critical equipment, and minimizing environmental impact. Industry leaders are taking note: installing top-tier filtration is not just about compliance, but can yield tangible returns in productivity, equipment longevity, and reputation for excellence in building management.

In summary, the future of HVAC filtration in 2025 and beyond is bright and full of innovation. We can expect smarter filters that “think” for themselves, materials science breakthroughs that make filters both ultra-fine and low-energy, and a continued elevation of indoor air quality as a pillar of building design. As one industry publication aptly put it, the latest filtration trends “ensure cleaner, healthier air for everyone” well into the future48. For commercial HVAC systems, that means an exciting era of growth where clean air technology and market demand go hand in hand. The buildings of tomorrow are breathing easier, and so are we.